Welding Rotators

- Home

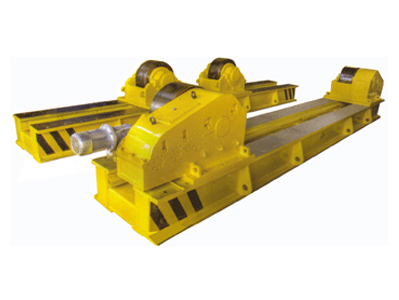

- Our standard Rotators consists of Drive Unit and Idler Unit. The frame and rollers brackets our fabricated rollers heavy section, stress relieved and precision machined.

- Overload disc to protect polyurethene roller

- Steplessely variable surface speed from 75 to 1500 mm/m or higher ratio and controlled through AC Variable Frequency Drives. For precision movement encoder feedbacks are provided on case to case basis

- Forward and Reserve rotation along with inching facility on panel.

- Operator pendant or forward / reserve inch or run speed varition ans stop functions

- An indispensable tool for shell fabrication shops

- Attains exceptional Quality circumferenatial joints on shells.

- Increased production with reduced labour skill.

- Leads to minimum handling the shell / Job.

- Lesser usage of crane reduces idle time.

- Improves plant efficiency.

- Welding automation.

We are Manufacturer, Supplier of Welding Rotators and our setup is situated in Pune, Maharashtra, India.

We manufacture the high quality rotators which are been used with various processes such as SAW / TIG / MIG / ARC etc., capacities upto 2000 Toons.. Steel rollers or polyurathene lined rollers are provided as per application. For higher capacity rotators forged rollers are provided.

Welding of Pipes, API pipes, Boilers, Heat exchagers, Pressure Vessels, Mounted vessels, LPG Bullets, Barrels, Tanks etc..

Construction of the machine is similar to that conventional type Rotators. However, the Roller Housing Brackets in this are supported directly on the machine bed and are attached to the bed only with an L.H. / T.H. Lead Screw and nuts. When the lead Screw is rotated with the ratchet handle, the Roller Brackets move simultaneously towards each other or away from each other. In this series there will be twin drive arrangement

Read MoreSelf Aligning Rotators automatically adjust the roller Housings to accept any job diameters with in the specified diameter range. This type of machines are generally used to cope with the change in shell diameter, Job to job. The roller housings of this type of machine are hinged ot the beds and to cope with the change in shell diameter job is introduced. In this type of rotator

Read More