We are Manufacturer, Supplier of Welding Turntables and our setup is situated in Pune, Maharashtra, India.

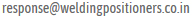

AEPL make Floor Turntables provides a high-precision, low-cost method of rotating a pipe, vessel or industrial work piece around a vertical axis. They also provide the added benefit of precise positioning in the flat or horizontal position. We have a wide range of solutions available for your applications and specialize in accommodating the most stringent design specifications. Each welding floor turntable is engineered to handle high capacities and speed while occupying minimal floor space. They are ideal for welding, flame cutting, thermal spraying, grinding, painting, X-ray. Out team can fully customize a turntable that is large or small for your application at the lowest profile possible.

| Technical Information | ||||

| Sr. No. | MODEL | CARRYING CAPACITY (Kg) |

TABLE DIAMETR (MM) |

MAX. TABLE HEIGHT (MM) |

| 1 | ATT-5 | 500 | 1000 | 350 |

| 2 | ATT-10 | 1000 | 1200 | 380 |

| 3 | ATT-25 | 2500 | 1500 | 425 |

| 4 | ATT-50 | 5000 | 2000 | 470 |

| 5 | ATT-100 | 10000 | 2500 | 600 |

| 6 | ATT-150 | 15000 | 2800 | 625 |

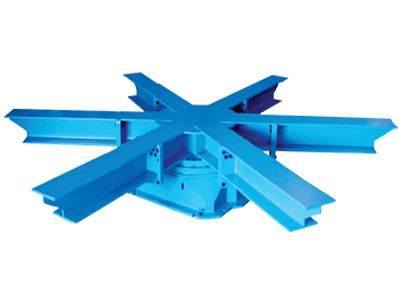

Through rotation and turning of Faceplate, positioners make work piece in best welding position. Robust all steel fabrication, variable speed table rotation.

| Technical Information | ||||||

| MODEL | APL0.5 | APL1T | APL2.5T | APL5T | APL7.5T | APL10T |

| Capacity (Tons) | 0.5 | 1 | 2.5 | 5 | 7.5 | 10 |

| Face Plate Diameter (mm) | 750 | 800 | 900 | 1000 | 1200 | 1300 |

| Horizontal Overhang (mm) | 750 | 900 | 1100 | 1250 | 1400 | 1600 |

| Rotational Axis Height (mm) | 900 | 1000 | 1150 | 1250 | 1450 | 1600 |

| Vertical Overhang (mm) | 150 | 250 | 275 | 300 | 325 | 350 |