We are Manufacturer, Supplier of Cladding Systems and our setup is situated in Pune, Maharashtra, India.

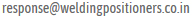

This is a fusion of Vertical and Horizontal weld overlay station. It is an unique Cladding Stations where in one can clad almost all kind of components. The structure comprises of XYZ slides and 2 rotators.

Features

- All Ac servo motors

- Base and bore cladding

- Auto AVC selection for ID & OD

- Weaving if required for face cladding

- AVC in bore and base

- Auto speed compensation for taper bore and face cladding

- Boom Up / Down Limit switch

- Virtual pendant on HMI

Dimensions

Overlay welding generally means applying an extra layer to metal base material using a welding procedure with the objective of achieving a higher wear resistance against abrasion, erosion, cavitation and corrosion. Weld overlays is needed in a number of industry sector where service conditions require corrosion resistant properties. The highly versatile welds overlay combination of readily available base materials, coated with a suitable corrosion resistant alloy to protect any given area. This provides the benefit of cost savings, as well as a reduction in lead time.

Features

- Higher production rate because of continuous processing.

- Fully automatic PLC controlled station with circumferential beads either in step or spiral increments.

- Servo controlled rotary and linear axes for precise positioning and restart of arcing from same point in case of power failure.

- AVC and auto pulsing facilities.

- Programming and storage facilities for all parameters.

- Reduce human error factors & less physical strain on welders especially on long welding/cladding process.

- Higher quality and productivity, especially with long duration welds.

- Lower processing cost.

Benefits

- Weld overlay is used for corrosion resistance or wear resistance and can be applied to extend the service life of new parts.

- The oil and gas industry is very familiar with the use cladding to mitigate corrosion in pipelines, flanges and other components.

Speciality

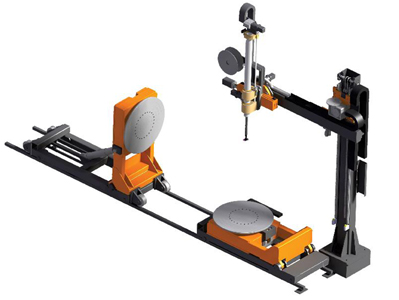

- 6"X 1" wall thickness can also be cladded on our system.

- Twin torch provision for cladding operation to reduce the t-ime.

Weld overlay system divided into three different segments ;

- HORIZONTAL WELD OVERLAY Cladding Stations

- VERTICAL WELD OVERLAY Cladding Stations

- UNIVERSAL WELD OVERLAY Cladding Stations

| Technical Information | |

| POINTS | DESCRIPTION |

| Job Size | Pipe OD 6" X 25THK TO 36" X 12.7 THK |

| Thickness | 9mm to 80mm |

| Pipe Length | 1.0 mtr to 12.5 mtr |

| Max pipe weight | 15 Ton |

| Welding Position | 1G |

Application

To carryout CRA weld overlay inside pipe.

Anvin offer fully automated TIG cladding welding systems for vertical valve-cladding applications. Complete turnkey packages include a wire-feed unit as well as a standard torch-programmable, cold-wire pulsed- TIG welding power source with an optional hot-wire system available for applications where higher deposition rate are required.

| Technical Information | |

| POINTS | DESCRIPTION |

| Job Size | Pipe OD 6" X 25THK TO 36" X 12.7 THK |

| Thickness | 12.7 mm to 80 mm |

| Pipe Length | Max. Elbow height - 2600mm |

| Max pipe weight | 7 Ton |

| Welding position | 1G & 2G |

Application

To carryout CRA spiral, circular and step increment wed overlay inside of pipe fitting and flanges, i.e. Pipe elbow, Tee, Reducer, Cap, Valve, profile, etc,.