We are Manufacturer, Supplier of Drum Tilting Devices, Drum Lifting Devices and our setup is situated in Pune, Maharashtra, India.

Anvin manufactures ergonomic barrel and drum handling equipment to lift, move, and pour drums, drum racks and drum handling forklift attachments. Anvin makes full line of industrial Drum Handlers i.e. Drum rollers, Drum Dumpers Drum Tilters and Drum Tumblers to mix the contents of your sealed drums. Anvin specialization is the, all our equipment's are designed to suitable to flame conditions. We have supplied our equipment's to oil and gas industries.

Industrial drum handlers as per following :

- DRUM TUMBLER

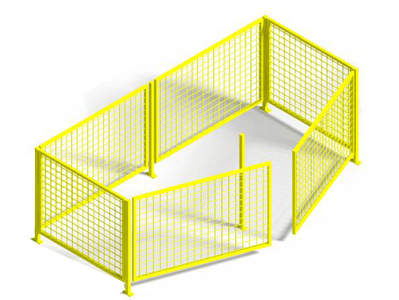

- DRUM ROLLER

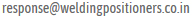

- DRUM TILTER

- DRUM DUMPER

A drum tumbler is the advanced factory - installed automated control package automatically lifts your drum, rotate for the time your set, and the returns it to upright position at floor-level for easy handling. The built-in-safety interlock on the enclosure automatically shuts off the drum rotator when the gate is opened.

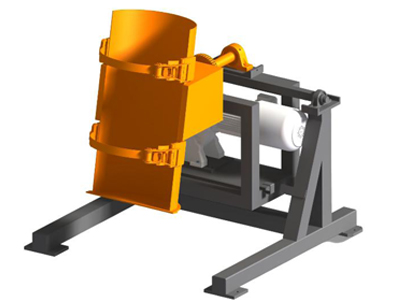

Guard enclosures for anvin drum tumbler have safety interlock to automatically sut off the drum roller when the gate is opened.

Rotating drum to mix or blend materials inside a closed drum saves time, labour and money. Rotates a drum to mix the contents, and ensure homogeneity with less hazards. Remix settled or stratified ingredients. Raise and redistribute solids that have settled during shipping and storage. Anvin customised drum handling equipment as per customer requirement or on basis of site condition & specialization in flame proof area.